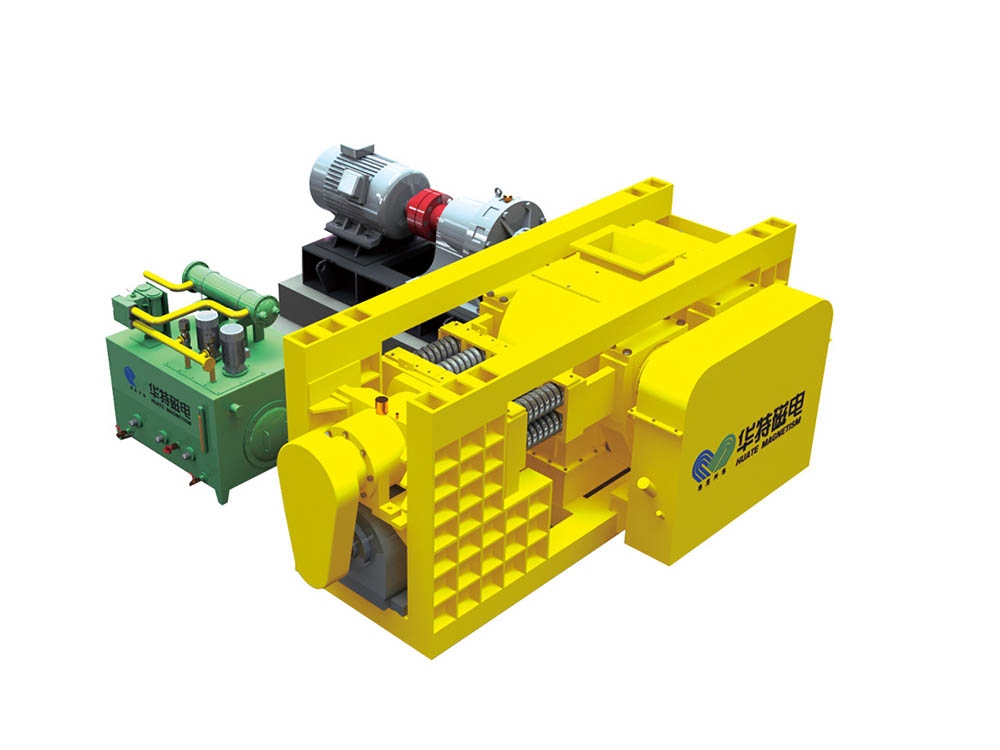

Series PGM Single Driving High Pressure Roller Mill

Sebaka sa Kopo

Ho na le mefuta e mengata ea lisebelisoa tsa tšepe Chaena, empa litšoaneleho tsa mefuta e mengata ea liminerale li fokola, li fapane ebile li ntle. E le ho rarolla mathata a hlahelletseng litabeng tsa moruo, tsa tekheniki le ts'ireletso ea tikoloho ea nts'etsopele ea merafo, likhoebo tsa merafo ea malapeng li kenya letsoho ka mafolofolo, li cheka le ho monya lisebelisoa tse ncha le tse sebetsang tsa tlhahiso ea merafo. Semelong sena sa 'maraka, HPGM ke lisebelisoa tsa ho sila tsa boleng bo holimo tse ileng tsa etsoa lipatlisiso le ho bontšoa,' me li qala ho sebelisoa likhoebong tsa merafo ea tšepe ea lehae. Hape ke thepa ea tlhahiso ea morafo e amehang haholo indastering ea merafo ea lehae. Ho ka boleloa hore HPGM e sebelisoa haholo merafong ea tšepe ea malapeng . HPGM e 'nile ea sebelisoa haholo lapeng le linaheng tse ling ka ho sila indastering ea samente, granulation indastering ea lik'hemik'hale, le ho sila hantle ha pellet ho eketsa sebaka se itseng sa holim'a metsi. tse kang ho nolofatsa mokhoa oa ho senya, ho senya le ho fokotsa ho fokotseha, ho ntlafatsa tlhahiso ea tsamaiso, ho ntlafatsa phello ea ho sila kapa lipontšo tsa karohano.

Molao-motheo oa ho Sebetsa

HPGM letoto la khatello e phahameng ea ho sila moqolo ke mofuta o mocha oa lisebelisoa tsa ho sila tse bolokang matla tse entsoeng ka molao-motheo oa khatello e phahameng ea lisebelisoa tsa pulverization. E na le lirolo tse peli tse petetsang tse potolohang ka mokhoa o lumellanang ka lebelo le tlase. E 'ngoe ke moqolo o emeng' me e 'ngoe ke moqolo o tsamaeang, oo ka bobeli ba khannoang ke enjene e matla a phahameng. Lisebelisoa li feptjoa ka mokhoa o ts'oanang ho tloha ka holim'a meqolo e 'meli,' me li tsoela pele ho kenngoa ka har'a lekhalo la moqolo ka moqolo o phunyeletsang. Ka mor'a hore u be tlas'a khatello e phahameng ea 50-300 MPa, kuku e teteaneng e ntšoa mochine. Kaka ea thepa e lahliloeng, ho phaella karolong e itseng ea lihlahisoa tse tšoanelehang, mohaho o ka hare oa likaroloana tsa lihlahisoa tse sa tšoanelehang o tlatsitsoe ka palo e kholo ea mapetsong a manyenyane ka lebaka la khatello e phahameng ea khatello, e le hore bokhoni ba ho sila ba thepa bo be teng. e ntlafalitsoe haholo. Bakeng sa lisebelisoa ka mor'a extrusion, ka mor'a ho senya, ho arola le ho hlahloba, lisebelisoa tse ntle tse ka tlaase ho 0,8 li ka fihla hoo e ka bang 30%, 'me thepa e ka tlaase ho 5 mm e ka fihla ho feta 80%. Ka hona, ts'ebetsong e tsoelang pele ea ho sila, tšebeliso ea matla a ho sila e ka fokotsoa haholo, e le hore bokhoni ba tlhahiso ea lisebelisoa tsa ho sila bo ka sebelisoa ka botlalo, ka kakaretso matla a tsamaiso ea bolo e ka eketsoa ka 20% ~ 50. %, mme kakaretso ea tšebeliso ea matla e ka fokotsoa ka 30% ~ 50% kapa ho feta.

Sekoaelo se Sebeletsang sa Kopo

1. Ho sila ka mokhoa o mahareng, o motle le oa ultrafine oa lisebelisoa tse ngata .

2. Lefapheng la ts'ebetso ea liminerale, e ka behoa ka pel'a leloala la bolo, e le sesebelisoa sa ho sila, kapa ho etsa mokhoa o kopantsoeng oa ho sila ka leloala la bolo .

3. indastering ea pellet e nang le oxidized, e ka nka sebaka sa leloala le nang le mongobo le sebelisoang hangata.

4.Ka thepa ea ho haha, lisebelisoa tsa refractory le liindasteri tse ling, li 'nile tsa sebelisoa ka katleho ka clinker ea samente, limestone, bauxite le ho sila tse ling.

Melemo ea Sehlahisoa:

1. Moralo oa khatello ea kamehla o tiisa khatello e boreleli pakeng tsa meqolo le ho netefatsa phello e sithabetsang.

2. Tokiso ea ho kheloha ka tsela e iketsang, e ka fetola ka potlako lekhalo la moqolo ho netefatsa boreleli ba lisebelisoa.

3. Tsamaiso ea karohano ea bohale e fokotsa phello ea liphello tse bohale ka phello e sithabetsang.

4. Ka lithupa tsa carbide tse entsoeng ka samente, bophelo bo bolelele ba ts'ebeletso, tlhokomelo e bonolo, le e ka nkeloang sebaka.

5. Banka ea li-valve e amohela likarolo tse tsoang linaheng tse ling, 'me tsamaiso ea hydraulic e na le moralo o utloahalang le botšepehi bo botle.

5. Th

Lihlahisoa tsa lihlahisoa

| Mohlala | Bophara ba roll mm | Roll bophara mm | Phello bokhoni | Boholo ba fepa | Boima ba mochini t | Matla a kentsoeng | |

| HPGM0630 | 600 | 300 | 25-40 | 10-30 | 6 | 74 | |

| HPGM0850 | 800 | 500 | 50-110 | 20-35 | 25 | 150-220 | |

| HPGM1050 | 1000 | 500 | 90-200 | 20-35 | 52 | 260-400 | |

| HPGM1250 | 1200 | 500 | 170-300 | 20-35 | 75 | 500-640 | |

| HPGM1260 | 1200 | 600 | 200-400 | 20-35 | 78 | 600-800 | |

| HPGM1450 | 1400 | 500 | 200-400 | 30-40 | 168 | 600-800 | |

| HPGM1480 | 1400 | 800 | 270-630 | 30-40 | 172 | 800-1260 | |

| HPGM16100 | 1600 | 1000 | 470-1000 | 30-50 | 220 | 1400-2000 | |

| HPGM16120 | 1600 | 1200 | 570-1120 | 30-50 | 230 | 1600-2240 | |

| HPGM16140 | 1600 | 1400 | 700-1250 | 30-50 | 240 | 2000-2500 | |

| HPGM18100 | 1800 | 1000 | 540-1120 | 30-60 | 225 | 1600-2240 | |

| HPGM18160 | 1800 | 1600 | 840-1600 | 30-60 | 320 | 2500-3200 | |

| bakeng sa litšupiso feela | |||||||

| [08] | |||||||

Lintlha tsa Tekheniki:

Theknoloji e ncha ea mofuta oa stud roll surface

E amohela li-studs tsa boleng bo holimo tse thata tse nang le boima bo phahameng le ho hanyetsa ho apara hantle. Tokisetso ea li-stud e entsoe ka mokhoa oa ho etsisa k'homphieutha, 'me tlhophiso e na le kahlolo e molemo, e ka etsang lera la thepa e ts'oanang pakeng tsa li-studs, ho sireletsa ka katleho li-studs le li-roll, le ho ntlafatsa bophelo ba tšebeletso ea ho penya moqolo . Li-studs li kentsoe ka likhomaretsi tse khethehileng tse tsoang kantle ho naha hore li nkeloe sebaka habonolo.

Theknoloji ea karohano ea li-roll bushing le shaft e kholo

'Mele o ka sehloohong oa moqolo o hatelitsoeng o entsoe ka tšepe e entsoeng ka boleng bo phahameng,' me roll bushing e entsoe ka tšepe ea boleng bo phahameng ba alloy . Mokotla o ka sehloohong le li-roll li entsoe ka lisebelisoa tse fapaneng, tse ntlafatsang ho tiea ha sefate se seholo le ho tiea ha roll bushing . Bophelo ba tšebeletso ea shaft bushing bo ntlafetse haholo. Ho nkela sebaka sa roll bushing ho loketse .

E na le theknoloji ea ho kenya le ho theola kapele

Li-bearings tsa sekoti tsa boleng bo holimo lia amoheloa 'me tanka ea oli ea khatello e phahameng e entsoe esale pele. Ho beleha ho ka theoloa habonolo ka pompo ea oli e nang le khatello e phahameng haholo, ho fokotsa haholo bothata ba ho nkela sebaka le ho ntlafatsa ts'ebetso ea tlhokomelo.

E na le theknoloji ea ho kenya le ho theola kapele

Li-bearings tsa sekoti tsa boleng bo holimo lia amoheloa 'me tanka ea oli ea khatello e phahameng e entsoe esale pele. Ho beleha ho ka theoloa habonolo ka pompo ea oli e nang le khatello e phahameng haholo, ho fokotsa haholo bothata ba ho nkela sebaka le ho ntlafatsa ts'ebetso ea tlhokomelo.

Theknoloji e mengata e kopantsoeng ea ho tiisa

Setiiso se behang se nka mefuta e fapaneng ea mofuta oa J-mofuta oa V-mofuta le li-labyrinth, 'me theknoloji e kopantsoeng ea ho tiisa e tiisa hantle phello ea ho tiisa ea ho beha.

Matla a phahameng a foreimi

Foreime e cheselitsoe ka tšepe ea boleng bo holimo ea carbon . Matla a foreimi kaofela a hlahlojoa ka mahlakore a mararo, a na le matla a phahameng le ho tšepahala ho hotle . The foreimi e sebetswa ka annealing bohlokoa le foreime deformation e nyenyane.

Sistimi ea hydraulic ea boleng bo holimo le e tšepahalang

Ho ea ka litšobotsi tse sithabetsang tsa lisebelisoa tse fapaneng, likhatello tsa khatello ea tsamaiso ea hydraulic li ntlafatsoa, 'me ho amoheloa moralo o khethehileng bakeng sa litšobotsi tse senyang tsa liminerale tsa tšepe tse kang tšepe ea tšepe le manganese ore. Sehlopha sa li-valve tsa hydraulic se amohela lihlahisoa tse tsebahalang tse tsoang kantle ho naha 'me sea tšepahala ebile se tsitsitse.

Sistimi ea taolo e ikemetseng le sistimi e bohareng ea lubrication

Ka Siemens PLC le skrine e feletseng ea ho ama, le morero oa ho laola ka ho feletseng, mochine oohle o ka ba o sa hlokomeloe, 'me khatello le likarolo tse fapaneng li ka fetoloa habonolo ho thusa ho senya liminerale tse fapaneng. Mochini oohle o sebelisa sistimi e bohareng ea lubrication, e ka fetolang palo ea lubrication le khafetsa ka maemo a ts'ebetso.

Sebaka sa Kopo