LHGC Intelligent Oli-Metsi Cooling Vertical Ring High Gradient Magnetic Separator

Boemo ba Khoebo

Shandong Huate Magnet Technology Co., Ltd, Mofani oa Ts'ebeletso ea Ts'ebeletso ea Ts'ebetso ea Ts'ebetso ea Magnetic, e thehiloe ka 1993,

mme e na le ntlo-khōlō ho Weifang, Chaena e nang le sebaka sa lisekoere-mithara tse 270,000 le basebetsi ba fetang 800. Huate Magnet e sebetsa ka ho khetheha ho hlahiseng matla a matla a makenete, lisebelisoa tsa karohano tsa matla a cryogenic superconducting, vertical ring high gradient magnetic separator (WHIMS), slurry electromagnetic separator, magnetic iron separator, magnetic stirrer, ultra-fine grinding and classifying equipment, merafong competing set equipment, medical magnetic separator. resonance imaging (MRI) joalo-joalo Sebaka sa tšebeletso se kenyelletsa morafo, mashala, motlakase, thepa ea mohaho, metallurgy, tšepe e se nang ferrous, tšireletso ea tikoloho, bongaka joalo-joalo ho feta masimo a 10. Ka bareki ba fetang 20,000, lihlahisoa tsa Huate li rometsoe linaheng tse 30 tse kang Jeremane, Australia, Czech Republic, India, Brazil le Afrika Boroa.

Lintlha tsa Setsebi

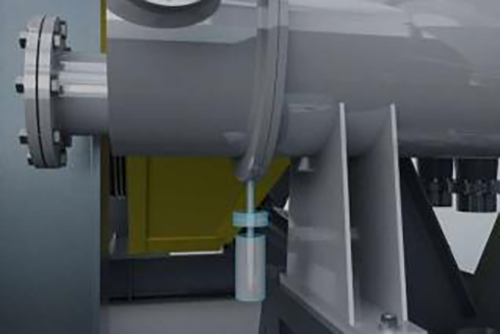

1. Oli-metsi Mocheso Exchange Cooling Technology

Coil e amohela phapanyetsano e kholo ea phallo ea kantle ea oli-metsi a mocheso bakeng sa ho qhala mocheso. Ho phahama ha mocheso oa coil ho ka tlase ho 25 ° C, ho fokotsa mocheso oa matla a khoheli ho nyane, 'me index ea ts'ebetso ea liminerale e tsitsitse. Coil e nka mohaho o tiisitsoeng ka ho feletseng, o sa keneleng pula, o thibela lerōle le ho senya, o ka ikamahanyang le maemo a sa tšoaneng a sebetsang a thata.

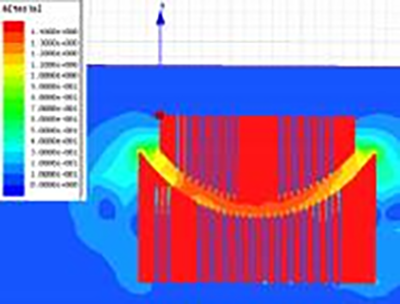

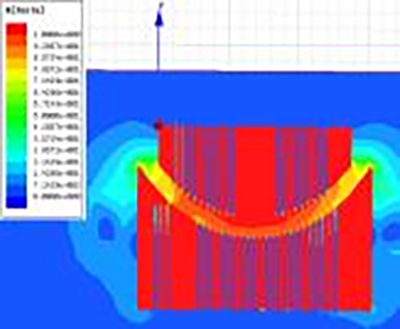

2. Moqapi o Nepahetseng oa Potoloho ea Magnetic

U sebelisa optimization element ea finite, moralo oa potoloho ea makenete oa utloahala, tahlehelo ea matla a makenete e nyane, 'me matla a matla a khoheli a ka fihla ho 0.6T, 0.8T, 1.0T, 1.3T, 1.5T, 1.8T.

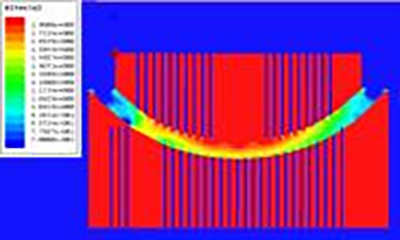

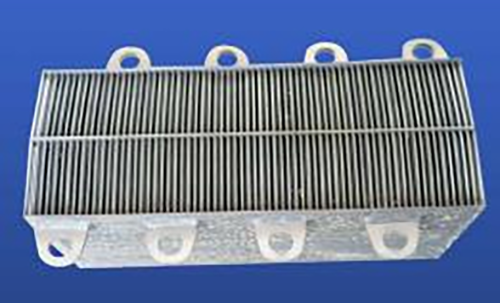

3. Nako e telele ea bophelo e kopantsoeng ke Magnetic Matrix

Matrix e nka sebopeho sa karolo e le 'ngoe,' me melamu e mahareng ha e oele; poleiti ea ho lokisa e nka moralo oa sebopeho sa conical, 'me matla a ho hokahanya a phahame; e cheselitsoe ka thepa e khethehileng ea liroboto, e nang le boleng bo tšepahalang le phapanyetsano e matla.

4. Sisteme ea ho lahla liminerale tsa Metsi a Flushing

Khatello ea metsi a phallang e fumanoa ka nako ea sebele, e le hore metsi a phallang a boloke khatello e lekaneng le ho phalla, 'me liminerale tse ka har'a matrix li ntšoa ka botlalo.

5. Sistimi ea Taolo ea Boemo ba Metsi

Boemo ba ho feto-fetoha ha boemo ba mokelikeli ba phaposi ea karohano bo bonoa ka nako ea nnete ke sensor ea ultrasonic, 'me e hokahane le actuator ea motlakase, e le hore boemo ba mokelikeli ba phaposi ea karohano bo lule bo le maemong a matle ka ho fetisisa a karohano; ts'ebetso ea matsoho e fokotsehile, 'me bothata ba ho hlahloba ka letsoho bo fokotseha; palo e feteletseng ea seretse hang hang e thibeloa ho qoba ho tlala.

6. Sistimi ea Tšireletso ea Alamo ea Mocheso

Li-sensors tsa mocheso oa li-coil li fanoa ho lemoha mocheso o sebetsang oa coil ka nako ea sebele le ho khutlisetsa boitsebiso setsing sa taolo. Ha mocheso oa li-coil o feta boleng bo behiloeng, tsamaiso e tla lla ka bo eona, 'me thepa e tla khaotsa ho sebetsa ha moeli o ka holimo o fihla ho netefatsa ts'ebetso e sireletsehileng ea lisebelisoa.

7. Leakage Alarm Device

Cooler e nka sebopeho sa li-tube-plate tse nang le mekhahlelo e 'meli,' me ho na le sesebelisoa sa ho lemoha ho lutla pakeng tsa lihlopha. Ha ho lutla ho etsahala, lisebelisoa li tla lla le ho emisa ka bo eona, e le ho qoba tšenyo ea coil e bakoang ke metsi a kenang ka har'a oli e pholileng.

8. Automatic Lubrication System

Sesebelisoa sa "ring drive" se sebelisa sesebelisoa sa ho tlotsa se iketselitseng sa gear ho etsa bonnete ba hore lisebelisoa li khona ho fumana lubrication ea othomathike ntle le ho emisa ts'ebetso le ho ntlafatsa sekhahla sa ts'ebetso.

9. Remote Intelligent Service Platform E Thehiloe ho Internet ea LinthoThekenoloji

Marang-rang a Lintho le mahlale a sethala sa maru a sebelisoa ho bokella le ho sekaseka lintlha tsa ts'ebetso ea lisebelisoa ka nako ea nnete ho hlokomela ts'ebetso le tlhokomelo e hole, tlhahlobo ea liphoso le taolo e felletseng ea potoloho ea lisebelisoa.

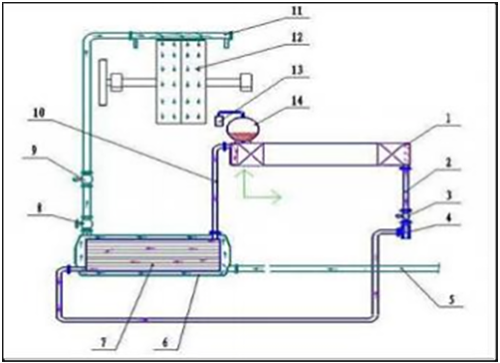

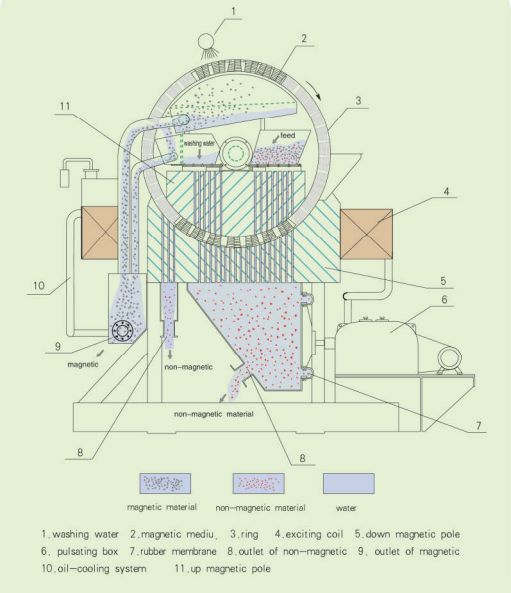

Molao-motheo oa Ts'ebetso

The slurry e hlahisoa ho hopper ea ho fepa ka phala ea phepelo, 'me e kena matrix a makenete holim'a selikalikoe se potolohang haufi le li-slots tse karolong e kaholimo ea makenete. Matrix ea makenete e na le makenete, 'me sebaka se phahameng sa makenete se hlahisoa holim'a sona. Likaroloana tsa makenete li hoheloa holim'a matrix a khoheli, 'me li tlisoa ho

sebaka seo e seng sa makenete ka holimo ka ho potoloha ha selikalikoe, ebe se tšeloa ka har'a hopper ea pokello ka ho phalla ha metsi ka khatello. Likaroloana tseo e seng tsa makenete li phalla ka har'a sehopo sa pokello ea lintho tse seng tsa makenete haufi le li-slots tsa palo e tlase ea makenete tse lokelang ho ntšoa.

Lisebelisoa

E loketse mahloriso a metsi a mefuta e fapaneng e fokolang ea tšepe ea tšepe e kang hematite, limonite, specularite, manganese ore, ilmenite, chrome ore, ore e sa tloaelehang ea lefatše, joalo-joalo, hammoho le ho tlosa tšepe le tlhoekiso ea liminerale tse seng tsa tšepe tse kang. quartz, feldspar le kaolin.

Lintlafatso

■Theknoloji ea ho futhumatsa metsi ka oli ea coil

■Sistimi ea ho ntša liminerale ka metsi a futhumetseng

■Sistimi ea ts'ireletso ea mocheso oa mocheso

■Automatic lubrication system

■Bophelo bo bolelele bo kopantsoeng matrix

■Sistimi ea taolo ea othomathike ea boemo ba mokelikeli

■Sistimi ea alamo ea ho lutla ha pholileng

■Intelligent remote monitoring system

Melemo ea LHGC Ho Feta Lesale la Tloaelehileng la setso WHIMS

| Lesale la setso le otlolohileng la WHIMS le amehang | Litharollo tsa LHGC |

| Coil e sebelisa terata e se nang letho le mokhoa oa ho pholisa metsi. Lerako le ka hare la terata le bonolo ho etsa sekala sa lime, 'me le tlameha ho hloekisoa ka acid kamehla, sekhahla sa ho hlōleha se phahame,' me bophelo ba coil bo khutšoanyane. | Coil e qoelisoa ka har'a oli bakeng sa ho pholisa, 'me e amohela ho potoloha ka ntle ho phallo e kholo, e nang le ho qhalana ha mocheso ka potlako, ho phahama ha mocheso o tlase le ho se lokisoe. Khetla ea coil e nka sebopeho se tiisitsoeng ka botlalo, se loketseng maemo a thata haholoanyane. |

| The rod matrix e oa habonolo | Matrix e nka sebopeho sa karolo e le 'ngoe,' me melamu e mahareng ha e oele; poleiti ea ho lokisa e amohela moralo oa sebopeho sa conical, se nang le matla a holimo a ho hokahanya 'me ha ho bonolo ho se senya. |

| Seretse se aparela | |

| Lubrication ka letsoho, boemo bo tlase ba polokeho | Lisebelisuoa tse sa sebetseng tsa lubrication, li bolokehile ebile lia tšepahala |

| Ts'ebetso le tlhokomelo ea matsoho,mosebetsi o boima | Taolo e bohlale, ts'ebetso e sa lebelloang |

The LHGC oli-metsi pholileng selikalikoe tse otlolohileng phahameng gradient magnetic separator (WHIMS)

(1.3T/1.5T/1.8T) Litekanyetso tse kholo tsa tekheniki: (liminerale tse seng tsa tšepe)

Ha e le hantle, khetho ea mohlala ea lisebelisoa e itšetlehile ka bongata ba slurry ea liminerale. ha ho aroloa liminerale ho sebelisoa.

mofuta ona oa thepa, slurry mahloriso na le tšusumetso e itseng holim'a liminerale processing index.To get better mineral processing index, ka kopo fokotsa slurry concentration hantle. Haeba karo-karolelano ea matla a khoheli a phepelong ea liminerale e phahame hanyane, matla a ho sebetsa a tla lekanyetsoa ho palo eohle ea ho ts'oara ea liminerale tsa makenete ka matla a khoheli.

matrix, tabeng, mahloriso a phepelo a lokela ho fokotsoa ka nepo.

| LHGC 1000F | LHGC 1250F | LHGC 1500F | LHGC 1750F | LHGC 2000F | LHGC 2250F | LHGC 2500F | LHGC 2750F | LHGC 3000F | LHGC 3500F | LHGC 4000F | LHGC 4500 | LHGC 5000F | ||

| E Faele Kamorao (T) | 1.3/1.5(1.8) Nako e sa fetoheng e lula e fetoha | |||||||||||||

| E fuoe lintlha tse monate (kW) | 25 | 36 | 38 | 46 | 56 | 60 | 72 | 82 | 90 | 105 | 118 | 130 | 140 | |

| 35 | 42 | 53 | 58 | 68 | 78 | 85 | 100 | 120 | 130 | 140 | 156 | 172 | ||

| 56 | 68 | 82 | 98 | 115 | 130 | 150 | 165 | 180 | 205 | 230 | 248 | 268 | ||

| Bokhoni (t/h) | 2 ho isa ho 3.5 | 5 ~9 | 10-15 | 15-25 | 25 ho isa ho 40 | 33-60 | 40 -75 | 50 ho isa ho 100 | 75 ho isa ho 125 | 125 ~ 200 | 175 ho isa ho 275 | 225 ~ 350 | 300 ho isa ho 480 | |

| Matla a pulp (m3/h) | 12.5 ho isa ho 20 | 20-50 | 50 ho isa ho 100 | 75 ho isa ho 150 | 100 ~ 200 | 160 ~ 300 | 200 -400 | 250 ~ 500 | 350 ho isa ho 650 | 550 ~ 1000 | 750 ~ 1400 | 1100 ho isa ho 1700 | 1200–2400 | |

| Nako e thabisang (A) | 50 | 80 | 130 | 135 | 150 | 175 | 172 | 200 | 207 | 217 | 262 | 280 | 288 | |

| 80 | 125 | 140 | 150 | 180 | 215 | 216 | 250 | 285 | 268 | 285 | 300 | 340 | ||

| 150 | 160 | 280 | 290 | 310 | 320 | 330 | 340 | 348 | 350 | 362 | 372 | 385 | ||

| Tšebeliso ea lijo (%) | 10 -35 | |||||||||||||

| Boholo ba lijo (mm) | -1.2 | |||||||||||||

| Lebelo la ho bilika (r/min) | 2 ~4 | |||||||||||||

| Sefate sa ka ntle sa selikalikoeφ (mm) | 1000 | 1250 | 1500 | 1750 | 2000 | 2250 | 2500 | 2750 | 3000 | 3500 | 4000 | 4500 | 5000 | |

| Matla a motlakase a Ring (kW) | 1.1 | 1.5 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | 37 | 45 | 55 | |

| Matla a thabisang (DCV) | (1.3T ~1.5T)0 ~514( Fetola ka ha jwale) /(1.8T)0~695 Fetola ka ya jwale) | |||||||||||||

| Khatello ea metsi (Mpa) | 0.2 ho isa ho 0.4 | |||||||||||||

| Tšebeliso ea metsi (m3/h) | 8-12 | 12-20 | 20-30 | 30 -50 | 50 ho isa ho 100 | 75 ho isa ho 125 | 100 ho isa ho 150 | 125 ~ 200 | 150 ho isa ho 250 | 250 ~ 350 | 350 ~ 500 | 450 ho isa ho 600 | 550 ~ 800 | |

| Boima ba karolo e kholo(t) | 2.8/3(4.7) | 3/6(12) | 9/14(20) | 14/19(22) | 20/22(28) | 22/23(30) | 24/25(32) | 25/26(34) | 33/36(38) | 50/52(55) | 70/72(75) | 74/77(80) | 80/82(85) | |

|

Bophahamo ba setšoantšo (mm) | L | 2360 | 2500 | 2670 | 2880 | 3810 | 4570 | 3660 | 3915 | 4410 | 4740 | 5470 | 5980 | 6410 |

| 2510 | 2780 | 2700 | 3000 | 3250 | 4620 | 3850 | 4260 | 4570 | 5530 | 5750 | 6160 | 6680 | ||

| 3120 | 3210 | 3760 | 3970 | 4170 | 4750 | 5200 | 5380 | 5510 | 5680 | 5820 | 6270 | 6820 | ||

| W | 2700 | 2880 | 3320 | 3540 | 4320 | 4590 | 4690 | 4840 | 5540 | 5860 | 6350 | 6630 | 6840 | |

| 2850 | 3420 | 3700 | 3900 | 4080 | 4600 | 5050 | 5130 | 5820 | 5930 | 6750 | 6890 | 7170 | ||

| 2520 | 3580 | 3630 | 4330 | 5040 | 5230 | 5400 | 5620 | 5800 | 6350 | 6900 | 7210 | 7330 | ||

| H | 2450 | 2860 | 3400 | 3710 | 4250 | 4800 | 5290 | 5760 | 6450 | 7435 | 8570 | 9200 | 9700 | |

| 2630 | 3000 | 3650 | 4060 | 4480 | 4850 | 5500 | 5960 | 6610 | 7200 | 8650 | 9480 | 9650 | ||

| 2490 | 3300 | 3800 | 4300 | 4800 | 5280 | 5760 | 6250 | 6730 | 7950 | 9150 | 9600 | 9800 | ||

The LHGC oli-metsi pholileng selikalikoe tse otlolohileng phahameng gradient magnetic separator (WHIMS)

(1.1T/0.6T) Litekanyetso tse kholo tsa tekheniki: (liminerale tse seng tsa tšepe)

| LHGC 1000F | LHGC 1250F | LHGC 1500F | LHGC 1750F | LHGC 2000F | LHGC 2250F | LHGC 2500F | LHGC 2750F | LHGC 3000F | LHGC 3500F | LHGC 4000F | LHGC 4500F | LHGC 5000F | ||

| Background Filed (T) | 1.1/(0.6) Nako e sa fetoheng e lula e fetoha | |||||||||||||

| E fuoe lintlha tse monate (kW) | ≤17/(10) | ≤19/(12) | ≤32/(15.5) | ≤37/(23) | ≤49/(29) | ≤51/(32) | ≤65/(41) | ≤69/(42) | ≤72/(50) | 93/(52) | 102/(58) | 110/(65) | 128/(75) | |

| Bokhoni (t/h) | 2 - 3.5 | 5 - 9 | 10-15 | 15-25 | 25-40 | 33-60 | 40-75 | 50 ~ 100 | 75-125 | 125 ~ 200 | 175 ~ 275 | 225 ~ 350 | 300 ~ 480 | |

| Matla a pulp (m3/h) | 12.5-20 | 20-50 | 50 ~ 100 | 75-150 | 100 ~ 200 | 160-300 | 200-400 | 200 ~ 500 | 350-650 | 550 ~ 1000 | 750–1400 | 1100–1700 | 1200-2500 | |

| Nako e thabisang (A) | 41/(70) | 70/(85) | 110/(110) | 120/(125) | 140/(130) | 146/(120) | 165/(120) | 225/(100) | 185/(150) | 205/(180) | 263/(205) | 270/(220) | 272/(330) | |

| Tšebeliso ea lijo (%) | 10-35 | |||||||||||||

| Boholo ba lijo (mm) | -1.2 | |||||||||||||

| Lebelo la ho bilika (r/min) | 2 -4 | |||||||||||||

| Ring bophara ba bokantle φ(mm) | 1000 | 1250 | 1500 | 1750 | 2000 | 2250 | 2500 | 2750 | 3000 | 3500 | 4000 | 4500 | 5000 | |

| Matla a motlakase a Ring (kW) | 1.1 | 1.5 | 3 | 4 | 5.5 | 7.5 | 11 (7.5) | 15 | 18.5 (15) | 30 | 37 | 45 | 55 | |

| Matla a thabisang (DCV) | 0~514(Fetola le ea hajoale)) | |||||||||||||

| Khatello ea metsi (Mpa) | 0.2–0.4 | |||||||||||||

| Tšebeliso ea metsi (m3/h) | 8-12 | 12-20 | 20-30 | 30-50 | 50 ~ 100 | 75-125 | 100 ~ 150 | 150 ~ 200 | 150 ~ 250 | 250 ~ 350 | 350 ~ 500 | 450 ~ 600 | 550 ~ 800 | |

| Boima bakeng sa kholo ka ho fetisisa Karolo(t) | 3.5/(2) | 4/(3.5) | 9.3/(4) | 15/(9) | 20/(13) | 24/(16) | 24/(17) | 21/(18) | 33/(25) | 50/(47) | 68/(60) | 72/(64) | 80/(72) | |

|

Kemiso tekanyo (mm) |

L | 2360 | 2780 | 3000 | 2970 | 3170 | 4400 | 3660 | 3915 | 4410 | 4900 | 5470 | 6670 | 7100 |

| 2260 | 2680 | 2900 | 2870 | 3070 | 4300 | 3650 | 3910 | 4150 | 7400 | 5310 | 6220 | 7000 | ||

|

W | 2700 | 3270 | 3320 | 3540 | 3810 | 4400 | 4690 | 4830 | 5540 | 5500 | 6240 | 7150 | 7650 | |

| 2600 | 3110 | 3220 | 3440 | 3710 | 4300 | 3785 | 3910 | 4630 | 7750 | 5910 | 6740 | 7130 | ||

|

H | 2480 | 2850 | 3330 | 3710 | 4250 | 4600 | 5290 | 5760 | 6450 | 4400 | 8520 | 8930 | 9600 | |

| 2380 | 2750 | 3230 | 3610 | 4150 | 4150 | 5175 | 5650 | 6280 | 7200 | 8340 | 8850 | 9380 | ||

Linyeoe tsa Sebaka

WHIMS e kholo ka ho fetesisa ea limithara tse 5 lefatšeng

Moketjana oa ho Qhala

Morero oa Morafo oa Tšepe Australia

Morero oa Morafo oa Tšepe Chaena

Morero oa Lehlabathe la Quartz naheng ea Austria