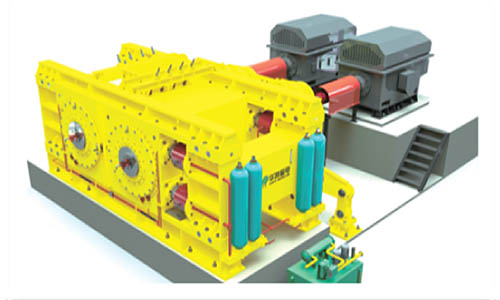

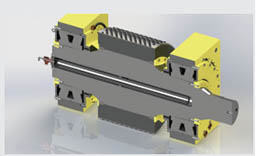

HPGM Series High Pressure Grinding Roll

Melemo ea Sehlahisoa:

1. Moralo oa khatello ea kamehla o tiisa khatello e boreleli pakeng tsa meqolo le ho netefatsa phello e sithabetsang.

2. Tokiso ea ho kheloha ka tsela e iketsang, e ka fetola ka potlako lekhalo la moqolo ho netefatsa boreleli ba lisebelisoa.

3. Tsamaiso ea karohano ea bohale e fokotsa phello ea liphello tse bohale ho phello e sithabetsang.

4. Ka lithupa tsa carbide tse entsoeng ka samente, bophelo bo bolelele ba ts'ebeletso, tlhokomelo e bonolo, 'me e ka nkeloa sebaka.

5. Banka ea valve e amohela likarolo tse tsoang linaheng tse ling, 'me tsamaiso ea hydraulic e na le moralo o utloahalang le botšepehi bo botle.

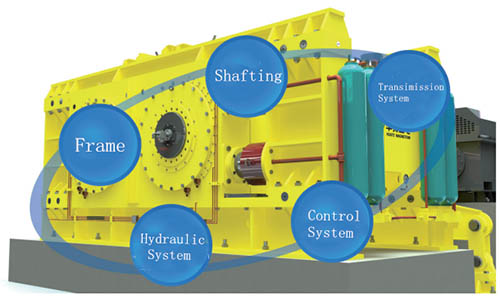

Likarolo tsa sebopeho sa HPGR:

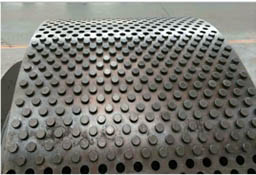

1. Theknoloji e ncha ea mofuta oa stud roll surface

E amohela li-studs tsa boleng bo holimo tse thata tse nang le boima bo phahameng le ho hanyetsa ho apara hantle. Tokisetso ea li-stud e entsoe ka mokhoa oa ho etsisa k'homphieutha, 'me tlhophiso e na le kahlolo e molemo, e ka etsang lera la thepa e ts'oanang pakeng tsa li-studs, ka katleho ho sireletsa li-studs le li-roll, le ho ntlafatsa bophelo ba tšebeletso ea ho penya moqolo. Li-studs li kentsoe ka likhomaretsi tse khethehileng tse tsoang kantle ho naha hore li nkeloe sebaka habonolo.

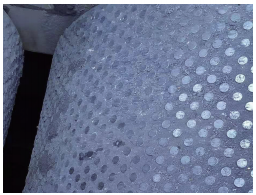

Lisebelisoa tse so ntlafatsoe

Boleng bo Phahameng ba ho Ruta bo Hanelang Bokaholimo bo nang le Li-Studs

Ka mor'a hore lisebelisoa li fetisetsoe, ho thehoa lesela le teteaneng holim'a moqolo ho sireletsa bokaholimo ba moqolo.

Keke ea lintho tse bonahalang

Theknoloji ea karohano ea li-roll bushing le shaft e kholo

'Mele o ka sehloohong oa moqolo o hatelitsoeng o entsoe ka tšepe ea boleng bo phahameng e entsoeng,' me roll bushing e entsoe ka tšepe ea boleng bo phahameng ba alloy. Mokotla o ka sehloohong le li-roll li entsoe ka lisebelisoa tse fapaneng, tse ntlafatsang ho tiea ha sefate se seholo le ho tiea ha li-roll bushing. Bophelo ba tšebeletso ea shaft bushing bo ntlafetse haholo. Ho nkela sebaka sa roll bushing ho loketse.

E na le theknoloji ea ho kenya le ho theola kapele

Li-bearings tsa sekoti tsa boleng bo holimo lia amoheloa 'me tanka ea oli ea khatello e phahameng e entsoe esale pele. Ho jara ho ka theoloa habonolo ka pompo ea oli e nang le khatello e phahameng, ho fokotsa haholo bothata ba ho nkela sebaka le ho ntlafatsa ts'ebetso ea tlhokomelo.

Theknoloji e mengata e kopantsoeng ea ho tiisa

Setiiso se behang se amohela mefuta e fapaneng ea mofuta oa J-mofuta oa V-mofuta le li-labyrinth, 'me theknoloji e kopantsoeng ea ho tiisa e tiisa hantle phello ea tiiso ea ho beha.

Matla a phahameng a foreimi

Foreime e cheselitsoe ka tšepe ea boleng bo holimo ea carbon. Matla a foreimi kaofela a hlahlojoa ka mahlakore a mararo, a na le matla a phahameng le ho tšepahala ho hotle. The foreime e sebetswa ka annealing bohlokoa le foreime deformation e nyenyane.

Sistimi ea hydraulic ea boleng bo holimo le e tšepahalang

Ho ea ka litšoaneleho tse sithabetsang tsa lisebelisoa tse fapaneng, likhatello tsa khatello ea tsamaiso ea hydraulic li ntlafatsoa, 'me ho amoheloa moralo o khethehileng bakeng sa litšobotsi tse senyang tsa liminerale tsa tšepe tse kang tšepe ea tšepe le manganese ore. Sehlopha sa li-valve tsa hydraulic se amohela lihlahisoa tse tsebahalang tse tsoang kantle ho naha 'me sea tšepahala ebile se tsitsitse.

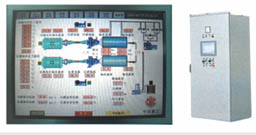

Sistimi ea taolo e ikemetseng le sistimi e bohareng ea lubrication

Ka Siemens PLC le skrine e feletseng ea ho ama, le morero oa ho laola ka kakaretso, mochine oohle o ka ba o sa lebelloang, 'me khatello le mekhahlelo e sa tšoaneng e ka fetoloa habonolo ho thusa ho senya liminerale tse fapaneng. Mochini oohle o amohela sistimi e bohareng ea lubrication, e ka fetolang palo ea lubrication le khafetsa ka maemo a ho sebetsa.

Melemo ea Morero oa HPGR: