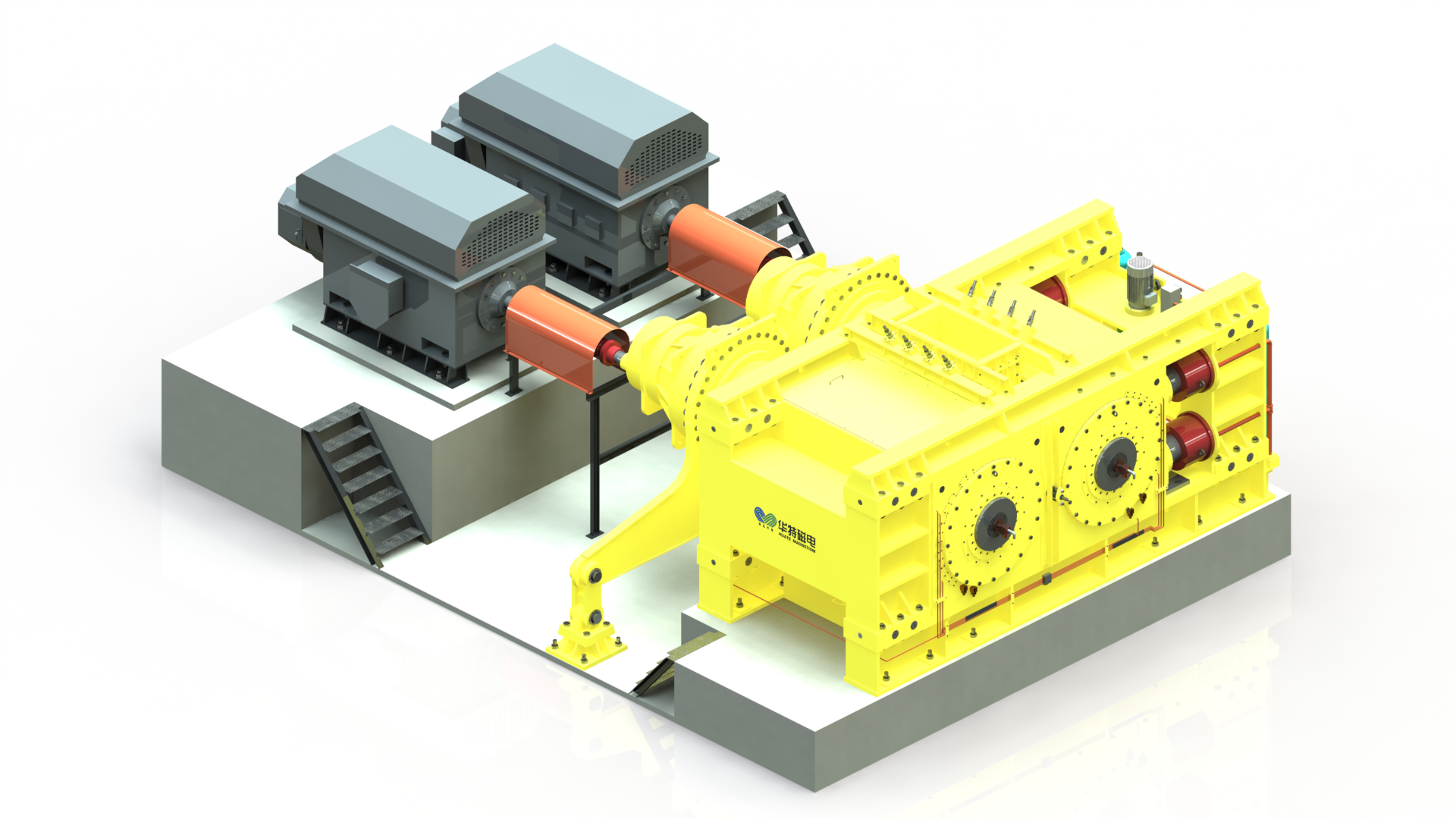

HPGM High Pressure Grinding Mill

Kopo

Ho na le mefuta e mengata ea lisebelisoa tsa tšepe Chaena, empa litšoaneleho tsa mefuta e mengata ea liminerale li fokola, li fapane ebile li ntle.E le ho rarolla mathata a hlahelletseng a moruo, botekgeniki le tshireletso ya tikoloho ya ntshetsopele ya merafo, dikgwebo tsa merafo tsa lehae tsa meepo di hlahisa, ho tjheha le ho monya disebediswa tse ntjha le tse sebetsang hantle tsa tlhahiso ya merafo kantle ho naha.Semelong sena sa 'maraka, HPGR ke lisebelisoa tsa ho sila tsa boleng bo holimo tse ileng tsa etsoa lipatlisiso le ho bonts'oa,' me li qala ho sebelisoa likhoebong tsa merafo ea tšepe ea malapeng.Hape ke thepa ea tlhahiso ea morafo e amehang haholo indastering ea merafo ea lehae.Ho ka boleloa hore HPGR e sebelisoa haholo merafong ea tšepe ea malapeng.HPGR e 'nile ea sebelisoa haholo lapeng le linaheng tse ling ho sila indastering ea samente, granulation indastering ea lik'hemik'hale, le ho sila hantle ha pellet ho eketsa sebaka se khethehileng.E sebelisoa bakeng sa ho sithabela ha tšepe ea tšepe ho finyella merero e fapaneng e kang ho nolofatsa mokhoa oa ho senya, ho senya le ho fokotsa ho sila, ho ntlafatsa tlhahiso ea tsamaiso, ho ntlafatsa phello ea ho sila kapa matšoao a karohano.

Molao-motheo oa ho Sebetsa

HPGM letoto la khatello e phahameng grinding roll ke mofuta o mocha oa lisebelisoa tsa ho sila tse bolokang matla tse entsoeng ke molao-motheo oa khatello e phahameng ea lera la pulverization.E na le lirolo tse peli tse petetsang tse potolohang ka mokhoa o ts'oanang ka lebelo le tlase.E 'ngoe ke moqolo o emeng' me e 'ngoe ke moqolo o tsamaeang, oo ka bobeli ba khannoang ke enjene e matla a phahameng.Lisebelisoa li feptjoa ka mokhoa o ts'oanang ho tloha ka holim'a meqolo e 'meli,' me li tsoela pele ho kenngoa ka har'a lekhalo la moqolo ka moqolo o phunyeletsang.Ka mor'a hore u be tlas'a khatello e phahameng ea 50-300 MPa, kaka ea thepa e teteaneng e lokolloa mochine.Kaka ea thepa e lahliloeng, ho phaella karolong e itseng ea lihlahisoa tse tšoanelehang, mohaho o ka hare oa likaroloana tsa lihlahisoa tse sa tšoanelehang o tlatsitsoe ka palo e kholo ea mapetsong a manyenyane ka lebaka la khatello e phahameng ea khatello, e le hore bokhoni ba ho sila ba thepa bo be teng. e ntlafetse haholo.Bakeng sa lisebelisoa ka mor'a extrusion, ka mor'a ho senya, ho arola le ho hlahloba, lisebelisoa tse ntle tse ka tlaase ho 0.8 mm li ka fihla hoo e ka bang 30%, 'me lisebelisoa tse ka tlaase ho 5 mm li ka fihla ho feta 80%.Ka hona, ts'ebetsong e tsoelang pele ea ho sila, tšebeliso ea matla a ho sila e ka fokotsoa haholo, e le hore bokhoni ba tlhahiso ea lisebelisoa tsa ho sila bo ka sebelisoa ka botlalo, ka kakaretso matla a tsamaiso ea bolo e ka eketsoa ka 20% ~ 50. %, mme kakaretso ea tšebeliso ea matla e ka fokotsoa ka 30% ~ 50% kapa ho feta.

Melemo ea Sehlahisoa

■ Moralo oa khatello ea kamehla o tiisa khatello e boreleli lipakeng tsa meqolo le ho netefatsa phello e sithabetsang.

■ Tokiso ea ho kheloha ka tsela e iketsang, e ka fetola kapele lekhalo la moqolo ho netefatsa boreleli ba lisebelisoa.

■ Tsamaiso ea karohano ea bohale e fokotsa phello ea liphello tsa bohale ho phello e sithabetsang.

■Ka lithupa tsa carbide tse samenteng, bophelo bo bolelele ba ts'ebeletso, tlhokomelo e bonolo, 'me e ka nkeloa sebaka.

■ Banka ea li-valve e amohela likarolo tse tsoang linaheng tse ling, 'me tsamaiso ea haeteroliki e na le moralo o utloahalang le botšepehi bo botle.

系列溢流型棒磨机MBY-G-Series-Overflow-Rod-Mill-300x225.jpg)