Sebaka sa ho hlopha sa matla a mahareng a matla a semi-magnetic a ho itokolla mehatla e na le sebaka se matla sa makenete, sebaka sa makenete se mahareng le sebaka se fokolang sa makenete.Polarity ea lipalo tsa makenete ka ho fapanyetsana e etsa semi-circle annular magnetic system.Karolo e 'ngoe ea khetla e qoelisoa ka har'a makhapetla,' me likaroloana tsa makenete ka har'a makhasi li lula li khabisoa ke mokhoa oa ho potoloha. lisebelisoa tsa makenete li lula li hlatsuoa.Ha ho na matla a khoheli karolong e kaholimo ho le letona la semi-ring magnetic system.Thepa e tšeloa ka tanka ea concentrate.

Likaroloana

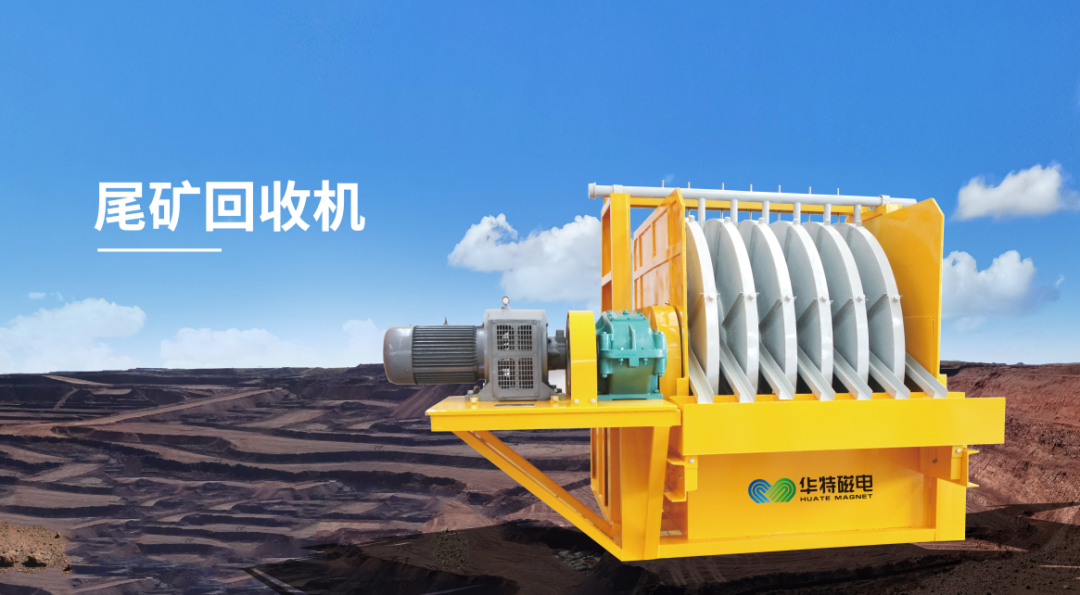

Mochini oa YCBW oa matla a mahareng a semi-magnetic o itlhohlolla mehatla o hlahisoang ke Khamphani ea Huate o na le litšobotsi tsa phello e ntle ea ho tiisa, ho ts'epaha ho phahameng le bophelo bo bolelele ba ts'ebeletso.

Sebakeng sa makenete, lihlopha tse ngata tsa lipara tsa magnetic pole tse nang le polarities tse fapaneng li hlophisitsoe ka ho fapanyetsana.Nakong ea ho potoloha, lisebelisoa tsa makenete li lula li phuthoa ka har'a poleiti ea ho bokella le metsi, li hlatsuoa le ho tlosoa, e le hore thepa ea makenete e tsosolositsoeng e be le bohloeki bo phahameng le phello e ntle ea ho hlaphoheloa.

Sebaka se fokolang sa makenete se behiloe lipakeng tsa sebaka sa matla a khoheli le sebaka seo e seng sa makenete ho disk ea makenete.Ha matla a khoheli a kena sebakeng seo e seng sa makenete, a feta sebakeng se fokolang sa phetoho ea matla a khoheli, 'me sebaka sa adsorption sa sebaka se fokolang sa matla a khoheli se fokotseha butle-butle.The deflector e boetse e thibela matla a khoheli hore a se ke a khutlela morao 'me e nolofalletsa ho tsoa ka potlako tlas'a ts'ebetso ea matla a khoheli le metsi a phallang.

Mokhoa oa phetisetso ea mofuta oa lebanta o qoba kotsi e patiloeng ea ho khathala ha enjene ka lebaka la ts'ebetso ea matla a khoheli.

Enjene e laolang lebelo la motlakase e amohetsoe, e leng bonolo ho e sebetsa ebile e ka sebetsoa ntle le litsebi, 'me litšenyehelo tsa tlhokomelo li tlase.

Lethathamo la ts'ebeliso le phello

Mochini oa YCBW oa matla a mahareng a semi-magnetic o itokollang mehatla o ntlafalitsoeng mme o hlahisoa ke Huate o ka khutlisa liminerale tse mahareng tsa makenete ka har'a slurry.

Sekontiri sa Anshan Iron le Steel se khethile lisebelisoa tse 8 tsa YCBW-15-8 bohareng ba lebala la matla a semi-magnetic ho laolla mehatla bakeng sa ho hlaphoheloa ha mehatla.Phello ea ho hlaphoheloa ke e latelang:

Mochini o hlabollang oa matla a mahareng a matla a semi-magnetic o itokollang: matla a ho sebetsa a makhasi ke 700-800m³/h, 'me matla a tšepe a tšepe ea ore ke 2.3-2.5%.Ka mor'a ho tsosolosoa ke mochine oa ho hlaphoheloa ha li-tailings, matla a tšepe a matla a masela a fokotsehile ho 0.5-0.7%, 'me phello ea ho hlaphoheloa e tsoteha.

Boholo ba lits'ebeletso tsa tekheniki tsa Huate Mineral Processing Engineering Design Institute

① Tlhahlobo ea likarolo tse tloaelehileng le ho lemoha lisebelisoa tsa tšepe.

②Ho tlosoa le ho hloekisa liminerale tse se nang tšepe tse kang quartz, feldspar, kaolin, bauxite, spodumene le pyrophyllite.

③ Tšebeliso ea tšepe, titanium, manganese, chromium, vanadium le lisebelisoa tse ling tse nang le ferrous.

④ Ho rua molemo ka liminerale tsa liminerale tse fokolang tsa makenete tse kang lefatše le sa tloaelehang, wolframite, tantalum-niobium, garnet le tourmaline.

⑤ Tšebeliso e felletseng ea lisebelisoa tsa bobeli joalo ka mehatla le mehatla e fapaneng.

⑥ Nonferrous metal mineral magnetic separation + matla a khoheli karohano kapa flotation le melemo e meng e kopanetsoeng.

⑦ Lirafshoa tse ntšo, tse se nang ferrous le tse seng tsa tšepe tse bohlale tsa ho hlopha.

⑧ Ts'ebetso ea phofo ea Ultrafine joalo ka ho silakanya lintho, ho sila bolo le ho hlopha.

⑨ Teko ea khetho ea liindasteri tse sa sebetseng hantle.

⑩ EPC turnkey merero e kang ho pshatla, khetho ea pele, ho sila, karohano ea makenete (e boima, e phaphametseng), le ho tsoa ho omileng ha limela tse sebetsanang le merafo.

Nako ea poso: Mar-28-2022