Ts'ebetsong ea karohano ea makenete ea magnetite, ka lebaka la agglomeration ea makenete, ho bonolo ho hlahisa "magnetic inclusions" le "non-magnetic inclusions", tse amang ka botebo boemo ba concentrates. Mochini o hlatsuoang le o tsepamisang mohopolo o ikemetseng o ikemetseng ke Walt ke moloko o mocha oa lisebelisoa tse arohaneng tsa matla a khoheli tse fokolang. E hlahloba ka ho feletseng matla a matla a matla a khoheli, matla a khoheli, matla a khoheli, matla a centrifugal, joalo-joalo Ha a kopane, lisebelisoa tsa ts'ebetso li fetoha ka tsela e iketsang ho ea ka thepa ea ore, e ka fokotsang ka katleho litaba tsa litšila tse kang silicon, phosphorus. , le sebabole ka har'a matla a khoheli, 'me u fumane lihlahisoa tse phahameng tsa magnetite le lihlahisoa tse mahareng tse kang tse tsepamisitsoeng ts'ebetsong ea karohano ea makenete, tse tšoanelehang esale pele. Khokahano ea ho qetela e loketse ts'ebetso ea melemo ea magnetite concentrator, e bulelang tsela e ncha bakeng sa mohopolo oa tšepe oa naha ea heso ho kenya tšebetsong leano la "ho ntlafatsa le ho fokotsa litšila".

Molao-motheo oa ho sebetsa

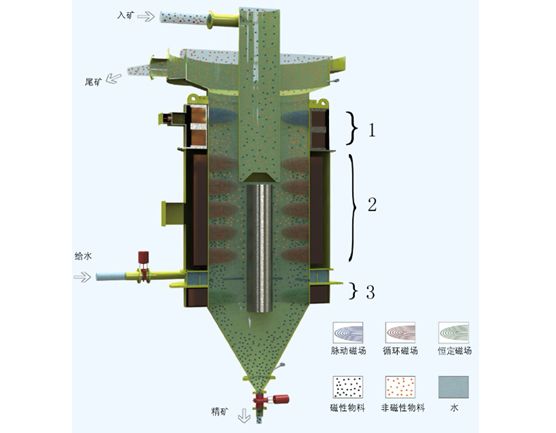

Ore e fepeloa karolong e bohareng le e ka holimo ea mochini oa elutriation ka mochini o fepang ore feeding hopper le peipi ea phepelo ea ore, 'me e hoholoa ke metsi a phuphuselang. Pakeng tsa li-coil tse peli le ha coil e tima, kaha matla a khoheli a theohang a fokotsehile haholo, a kuta 'me a qhalakanngoa ke phallo e phahameng ea metsi a potolohang holimo, e le hore gangue e le' ngoe, slime ea tšepe le lintho tse phelang tse kopantsoeng li kopane ho eona. , haholo-holo mafutsana a kopanetse lintho tse phelang. Lebanta le mathang le ea holimo, 'me tlas'a ketso ea ho phalla ha metsi ho ea holimo ho matla, le nyolohela moeling oa ho phalla' me le lokolloa hore e be mehatla e entsoeng haholo-holo ka 'mele e kopantsoeng.

Molao-motheo oa ts'ebetso oa mochini oa khetho ea electromagnetic panning

Liminerale tsa makenete ka har'a ore li hoheloa ke matla a khoheli a hlahisoang ke khoele ea motlakase, 'me likaroloana tsa magnetized ore li fetoha dipoles tsa makenete,' me li-dipole tse ngata tsa makenete li hohelana ho theha liketane tsa makenete. khokahanyo ea ho tima motlakase e qhalakanngoa ka ho feletseng ke ho kuta ka axial tlas'a ketso ea ho phalla ha metsi ka lebelo le phahameng le ho phahama. Ts'ebetso ena e etsoa ka makhetlo a mangata, e le hore lisebelisoa tsa khoheli li ka khethoa ka makhetlo a mangata mochining oa elutriation ho fumana concentrate ea magnetite e phahameng, 'me ka nako e ts'oanang, litaba tsa litšila tse kang SiO2 le tsona li fokotsehile.

Mokhoa oa ho laola mochine oa ho hlatsoa

Mochini oa elutriation o nka taolo ea li-impulse tse peli, ke hore, khatello ea likhahla le khatello ea metsi e tlaase ke lipakane tsa taolo.Tlhaloso ea ho phalla e laoloa ke boholo ba matla a matla a khoheli, 'me khatello e tlaase e laoloa ke ho buloa ha tlase. Setsing sa taolo, ka ho beha litekanyetso tse shebiloeng tsa mahloriso a phallo le khatello e tlase ea metsi, sistimi ea taolo e nka algorithm e bohlale ea ho laola matla a matla a khoheli le ho bula valve e tlase ho boloka boleng ba sepheo ka har'a sebaka se itseng sa ho sebetsa. .

Ha tekanyo ea ho fepa ea ore e sa tsitsa, tsamaiso ea taolo e tla fetola valve e ka tlaase ho ea ka phetoho ea khatello ea metsi ka har'a mochine oa elutriation, e le hore motlakase o ka hare ho mochine oa elutriation o lule o sa fetohe 'me o boloka sebaka se tsitsitseng sa ho hlophisa; phepelo ea metsi ha e tsitsa, tsamaiso ea taolo e fetola matla a matla a khoheli ho ea ka phetoho ea khatello e feteletseng ea mochine o hlatsoang ho netefatsa botsitso ba index ea concentrate.

Mochini o ikatisang oa motlakase oa ho penya le ho khetha o sebelisa mokhoa o tsoetseng pele oa PID-automatic optimization control, o sa hlokeng mosebetsi oa matsoho mme o lula o sebetsa maemong a matle. lifaele li thehoa bakeng sa lisebelisoa tsa ho laola nako eohle ea bophelo; Litsebi tsa ts'ebetso ea liminerale tsa k'hamphani ea rona li ka fetola ka thōko mekhoa ea ho lokisa liminerale ea mochine oa ho hlatsoa ka sethala sa ho shebella se hole ho sebeletsa basebelisi hamolemo.

Nyeoe ea ts'ebeliso ea mochini oa khetho ea electromagnetic panning

Nako ea poso: Mar-21-2022